Solid Wall Technology

Up to 5% Material Savings

Solid Wall Extrusion Technology

Solid wall extrusion technology is used for manufacturing pipes that consist of a single, homogeneous layer of PVC. Unlike multi-layer pipes, which are produced by combining different polymers or materials, solid wall pipes rely on the uniform characteristics of one material throughout the entire cross-section.

This technology is particularly suitable for applications where durability, material consistency, and predictable mechanical properties are essential. The homogeneity of the pipe wall ensures even performance under pressure, resistance to chemical and environmental influences, and long-term structural stability.

Applications of Solid Wall PVC Pipes

Solid wall pipes are suited for both pressure and non-pressure applications across several industries:

-

Sewage Infrastructure: High stiffness for underground installation and smooth bore for blockage prevention.

-

Construction and Building: Easy to cut and assemble; ideal for indoor drainage and ventilation systems.

-

Telecommunication Ducting: Provides reliable mechanical protection and easy handling during installation.

%20(1).png?width=1000&height=1000&name=Social%20post%20(12)%20(1).png)

The Benefits of Solid Wall Technology

1. Enhanced Product Quality and Consistency

-

Precise Wall Thickness: Advanced flow control eliminates unnecessary wall thickness, reducing material usage by 3–5% compared to coat-hanger-type die-heads.

-

Weld Line Integrity: Improved compression and flow dynamics lead to virtually invisible weld lines, enhancing mechanical strength and long-term performance.

2. High Operational Efficiency

-

Increased Throughput: The reduced residence time allows for higher production speeds or better pipe quality at existing rates.

-

Faster Changeovers: Modular die-head construction simplifies installation, maintenance, and tooling changes. Features like “Smart Centering” retain alignment during die swaps, minimizing scrap. “Quick Tool Change” functions reduce downtime during production transitions.

3. Material and Cost Optimization

-

Lower Material Consumption: More accurate wall thickness control minimizes overuse of raw material.

-

Reduced Formulation Costs: Smaller internal die-head volumes require less stabilizer and other additives.

-

Lower Maintenance Overhead: Modular design reduces time and labor needed for cleaning, servicing, or reconfiguring the die-head.

-

Faster Return on Investment: Material savings of 5% and maintenance/integration cost reductions of 10% can lead to ROI within one year.

4. Sustainability

-

Efficient Waste Management: Shorter start-up times and rapid material stabilization reduce scrap and off-spec production.

-

Energy Efficiency: Reduced pressure loss and improved heat transfer contribute to lower overall energy consumption.

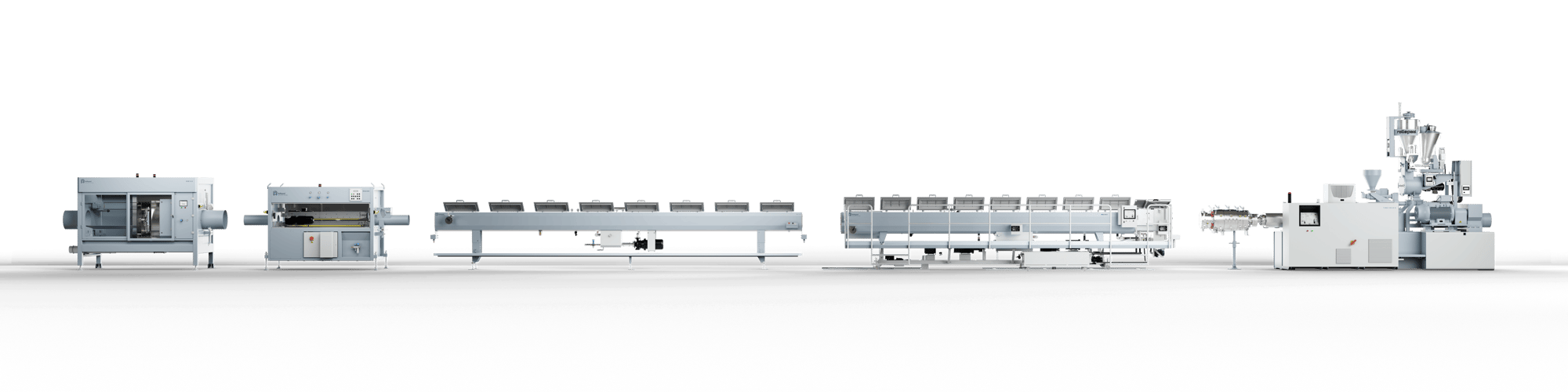

Required Equipment

A series of equipment is required to ensure the production process’s quality, efficiency, and precision. Below is an overview of the key equipment used in the manufacturing of Solid Wall pipes.

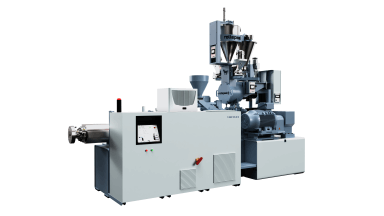

1. Extruders

In the production of solid wall PVC pipes, the primary extruder is a key component. It uses a rotating screw to melt and homogenize the PVC compound, ensuring a consistent flow of material. This process allows for the continuous formation of a uniform pipe wall with precise dimensions and high surface quality.

Read more about Twin Screw Extruders

2. Gravimetric Systems

Gravimetric systems are measurement devices that regulate material feeding into extruders, ensuring consistent output and minimizing waste.

Rollepaal Gravimetric Systems optimize material flow for stable extruder output, even with bulk density fluctuations. Their automated calibration reduces overweight and ensures precise dosing. Designed for efficient mass flow, these systems enhance productivity while minimizing waste and costs.

Read more about Feeders & Gravimetrics

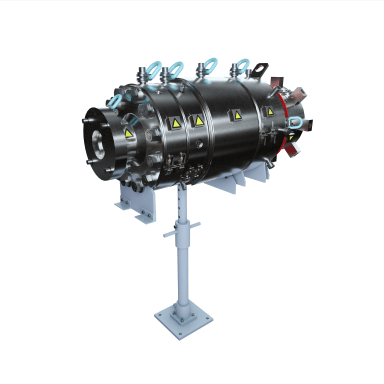

3. Solid Wall Die-Head

Rollepaal solid wall die heads are designed with advanced branching technology and a dual compression system. This combination ensures that molten PVC is evenly distributed around the pipe circumference, compensates for viscosity variations, and minimizes internal stress. The result is consistent wall thickness, stronger weld lines, and superior pipe integrity.

Read more about Solid Wal Die Heads

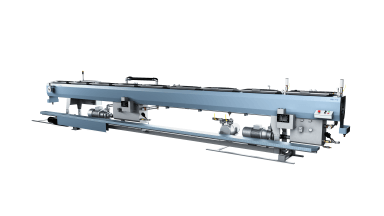

4. Cooling System

The formed pipes must be cooled rapidly to maintain their shape and structural properties. Two types of cooling units are typically used:

Vacuum Cooling: This method rapidly cools pipes after extrusion by applying a vacuum to prevent ovality of the pipe.

Spray Cooling: Positioned after the vacuum cooling section, this system sprays water under atmospheric conditions for additional cooling and optimal results.

Read more about Cooling Units

5. Haul-Off

These units are responsible for drawing the extruded pipe through the cooling system at a consistent speed, ensuring uniform pipe dimensions and preventing deformation.

To protect the pipe surface, our haul-offs feature rubber blocks that cushion against direct contact, reducing the risk of scratches, dents, or imperfections. This ensures high-quality production that meets customer expectations.

Read more about Haul-Offs

6. Cutting and Chamfering Machines

Cutting and chamfering machines are utilized to finish the pipe to its required length and prepare the ends for connection.

Rollepaal's pipe cutters are designed to change to a different pipe size quickly and easily without exchanging parts.

Read more about Pipe Cutters

With this equipment in place, manufacturers can deliver superior Solid Wall pipes that combine durability, consistency, and cost savings. Each part of the system works together to ensure peak efficiency and reliable output across the entire production line.

Compliance

Rollepaal Solid Wall Technology is designed to meet international pipe manufacturing standards such as ISO, AWWA, and ASTM.