Solid Wall Die Heads

PVC Pipe Extrusion with Precision and Efficiency

Solid Wall Die Heads

Our Solid Wall Die Heads are designed to revolutionize your extrusion process, delivering exceptional performance and precision. With our advanced technology and engineering expertise, we have developed a range of die heads that ensure superior quality and efficiency in your production. Discover the benefits of our Solid Wall Die Heads and take your extrusion capabilities to new heights.

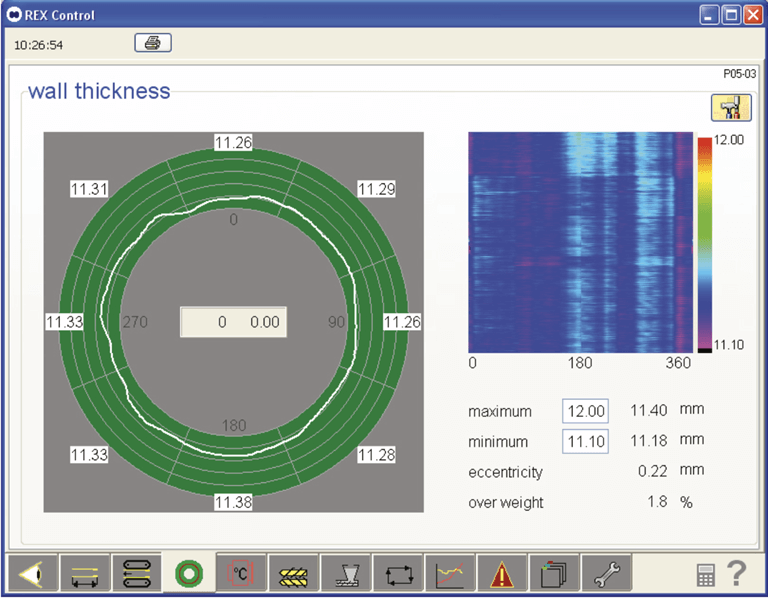

Precision Wall Thickness Control: Ensure high-quality extrusions with precise and uniform wall thickness

Our Solid Wall Die Heads feature advanced technology that ensures precise wall thickness control, resulting in high-quality extrusions. Integrated within a modern PVC extrusion machine, this precision enables uniform wall thickness, allowing for consistent product dimensions and minimizing the need for additional trimming or rework. This not only saves you time and resources but also enhances the overall quality of your extruded pipes.

Optimal Melt Flow Distribution

Uneven melt flow can lead to defects or inconsistencies in the final product. Our Solid Wall Die Heads are engineered to provide optimal melt flow distribution, ensuring uniformity throughout the extrusion process. This eliminates the risk of product defects and enables you to deliver superior quality extrusions to your customers.

Easy Die Gap Change for Optimal Performance

We understand that different extrusion applications require varying die gaps. Our Solid Wall Die Heads feature an easy-to-use die gap change mechanism, allowing you to quickly fine-tune the settings for optimal performance. With precise control over the die gap, you can achieve the desired extrusion outcomes with ease, saving time and ensuring consistent quality.

High Productivity and Reduced Downtime

Our Solid Wall Die Heads are designed for high productivity, allowing you to extrude more products in less time. With their optimal design, they minimize heat accumulation, reducing the risk of overheating and downtime. This translates to increased productivity, shorter lead times, and improved profitability for your business.

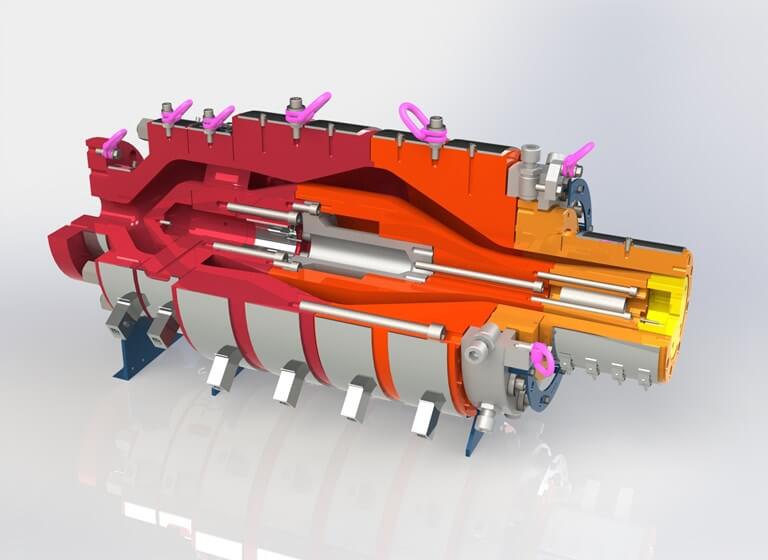

Modular Design for Versatility and Easy Maintenance

We understand that maintenance and adaptability are vital aspects of any extrusion process. Our Solid Wall Die Heads feature a modular design, allowing for easy disassembly and reassembly. This simplifies maintenance tasks and reduces downtime. Additionally, the modular design enables you to easily upgrade or customize your die head to meet evolving production requirements.

Maximize Efficiency with Quick Tool Change: Streamlined Adjustments

With Rollepaal's Quick Tool Change option, we ensure maximum efficiency in your pvc pipe manufacturing machine operations. Our technology facilitates rapid wall thickness and diameter changes up to 250, significantly minimizing operational downtime in your pvc extrusion line. We also offer a simplified change process for ranges above 250, demonstrating our commitment to creating solutions that align with the diverse requirements of your pvc pipe production line. Our Quick Tool Change option exemplifies Rollepaal's dedication to innovation that delivers tangible time savings and efficiency improvements, trusted by leading pvc pipe extrusion machine manufacturers worldwide.

Unmatched Excellence with Double Compression Design

Rollepaal's Double Compression Design empowers you to achieve flawless spider line welding. This feature, facilitated by our cutting-edge computational design resources, redefines the performance benchmarks for extrusion processes. The double compression design promotes superior welding results compared to other solid wall die heads in the market, while ensuring optimal resource usage. The durability, reliability, and precision delivered by our Double Compression Design are the best in the market, reflecting Rollepaal's unwavering commitment to providing solutions for improved process efficiency and product quality.

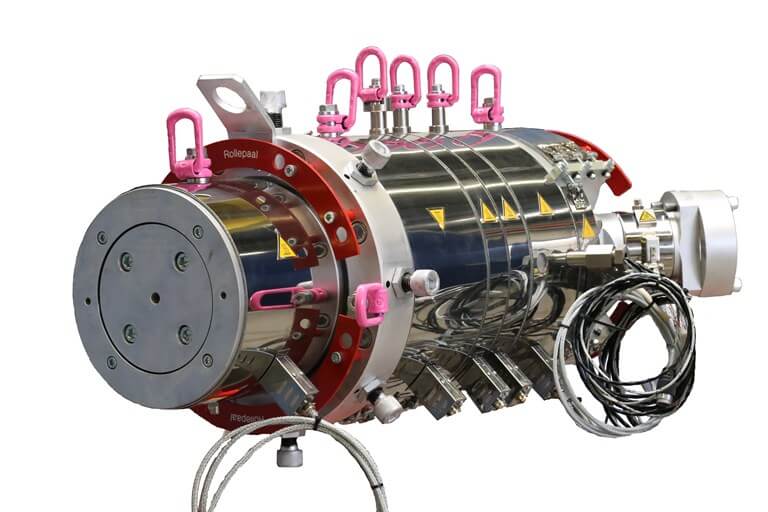

Durable Construction for Long-Lasting Performance

Our Solid Wall Die Heads are built to last, with robust construction and high-quality materials. Designed and engineered for reliability, they can withstand the demands of continuous extrusion operations. By investing in our die heads, you can experience long-lasting performance, minimizing the need for frequent replacements and maximizing your return on investment.

Superior Control with Thermal Centring

Experience heightened levels of control in your extrusion processes by implementing Rollepaal's Thermal Centring feature. Our die heads are equipped with temperature control zones that have been meticulously engineered to enable rapid adjustments of wall thickness, delivering exceptional precision and consistency. Thermal centring not only ensures efficient operations but also guarantees high-quality results. Using Thermal Centring, wall thickness changeover time goes between three to six minutes, diameter change from six to twelve minutes and the range change between twelve and twenty minutes, depending on diameter range. It is worth noting that the mentioned changeover times can be achieved if the tools have been pre-heated and QTC hoist tools are available. Still, the most critical factor that can affect achieving these times is organizational proficiency. To meet the specified times, you need personnel who are well-trained and fully prepared.

Product Sheet

Solid Wall Die Heads

Explore the technical specifications of our Solid Wall Die Heads and unleash their potential in your extrusion process.