About Rollepaal

Years

Employees

Installed Machines

Benefit from state-of-the-art plastic pipe extrusion machines equipped with integrated business software designed to automate and refine your production process. Our focus on advanced plastic processing ensures that you can achieve optimal performance, enhanced productivity, and a competitive edge in your manufacturing operations.

Enhance Your Production Capabilities

Leveraging our deep expertise in PVC pipe extrusion technology, you can tailor your production processes to meet unique demands and elevate your manufacturing efficiency.

Maximize Machine Lifespan and Performance

By selecting only high-quality materials and components, we help ensure that your operations benefit from machines that are both reliable and durable, minimizing downtime and maximizing productivity.

Drive Environmental Sustainability

Collaborate with us to innovate and implement manufacturing solutions that reduce raw material usage and increase the incorporation of recycled materials, helping you contribute to environmental sustainability while maintaining operational excellence.

Our Mission

At Rollepaal our mission is to do our part in seeing that everyone has access to clean water and sanitation by supplying innovative pipe extrusion technology.

It’s with this in mind that we actively contribute to the success of our customers by offering sustainable cost saving solutions. The modern Rollepaal pipe extrusion machinery minimises the consumption of raw materials while enabling the use of recycled materials.

Reuters’ 50 Leaders of Change

Rollepaal has been named one of Reuters’ 50 Leaders of Change. A series that explores the future state of global business, and follows innovative and sustainable companies leading the way toward a new tomorrow. The series contains a movie in which we give you an insight into how we enable clean water and sanitation for everyone through supplying innovative plastic pipe extrusion technology. The film shows our unique technology which allows for producing high-quality, reliable, and corrosion-resistant pipes with fewer materials, energy, and labor than traditional methods.

Check the trailer of the series, and our movie, of course!

Cost saving solutions

Rollepaal equipment is known for its quality, with a focus on sustainability. Raw materials are the largest cost component in the manufacture of plastic pipes, with materials comprising about 80% of the manufacturing costs. Given this fact, it’s worthwhile to reduce overweight and/or increase CaCo3 content, while still ensuring the pipe meets the required specifications. Rollepaal equipment enables pipe producers to produce with less scrap and control the quality of the pipe during production.

Our History

Since its founding in the 1960s Rollepaal has had an eventful history. For many years Rollepaal was part of Europe’s biggest pipe producer, giving the company the chance to learn all about pipe manufacturing from the customer’s point of view.

Origin of our name

Our name Rollepaal originates from the industrial estate of the same name, where Rollepaal is located. Originally a rollepaal or rolpaal (literally ‘roll post’) was a stationary post that was used for boats being pulled in inland navigation. A person or horse towed the boat with a rope to guide it safely along the canals. These posts were located at spots where the canal made a turn. By keeping the rope strained around the post, the boat was able to make the turn without bumping into the side of the towpath.

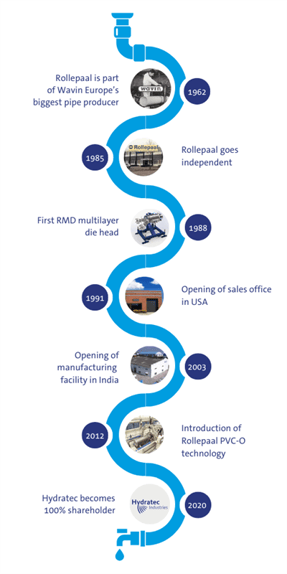

Milestones

In the timeline you see a chronology of significant events and milestones in Rollepaal's history.

These milestones highlight Rollepaal's continuous growth, technological advancements, global expansion, and strategic partnerships throughout its history. As an industry leader, Rollepaal remains committed to providing cutting-edge solutions and delivering exceptional value to its customers in the pipe extrusion technology field.

Timeline