PVC-O Technology

Double the length of pipe with the same amount of raw material.

PVC-O Technology

PVC-O (Biaxially Oriented Polyvinyl Chloride) technology represents a significant advancement in pipe manufacturing. By stretching raw PVC-U in axial and radial directions during the polymer extrusion process on a pipe production machine within a modern plastic pipe extrusion line, we alter its mechanical properties, creating stronger, more flexible, and highly durable pipes. These attributes make PVC-O an excellent choice for high-pressure applications, particularly in water pipe installations.

%203.jpg?width=450&height=262&name=Featured%20Image%20(450x263px)%203.jpg)

The benefits of PVC-O

-

Superior Strength: PVC-O pipes deliver exceptional resistance to impact and crack propagation, ensuring long-lasting performance.

-

Longevity and Durability: Designed to withstand challenging conditions, these pipes offer remarkable longevity, providing reliable service and peace of mind for end-users. PVC-O pipes exhibit the highest resistance to oxidizing media, natural oil-based substances, and diluted water, ensuring a long service life.

-

High Minimum Required Strength (MRS): PVC-O has the highest MRS class (500) compared to PE (max. MRS class 100). This means thinner, lighter pipes.

-

High Flow Capacity: The smooth internal surface significantly reduces friction, enhancing flow rates and reducing energy costs. With the same diameter and pressure class, PVC-O transports 34% more water than PE.

-

High Impact Resistance: Even at low temperatures (minus 20 degrees Celsius), PVC-O pipes maintain excellent impact resistance.

-

Flexible Bending: PVC-O's low bending resistance allows for easy pipe curving.

-

Cost-Effective: PVC-O reduces material consumption by up to 64% compared to uPVC pressure pipe. Lower production costs make PVC-O an economical choice for manufacturers and end-users.

-

Sustainability: With lower raw material usage and recyclability, PVC-O is an environmentally friendly option.

-

Compliance with Standards: Our PVC-O pipes exceed standards like ISO 16422 and AWWA C909, ensuring top-tier quality.

Advantages Compared To Traditional Solutions

In addition to the benefits of PVC-O pipes, they have advantages compared to other traditional pipe materials.

- Lower Carbon Footprint: PVC-O has a significantly lower carbon footprint than traditional solutions like ductile iron and concrete, making it an environmentally friendly option.

- Corrosion Resistance: Corrosion is a significant problem in ductile iron pipes. With PVC-O, this issue is eliminated.

- Superior to PO Solutions: PVC-O outperforms other polyolefin (PO) solutions like PE100 in water pipe installations.

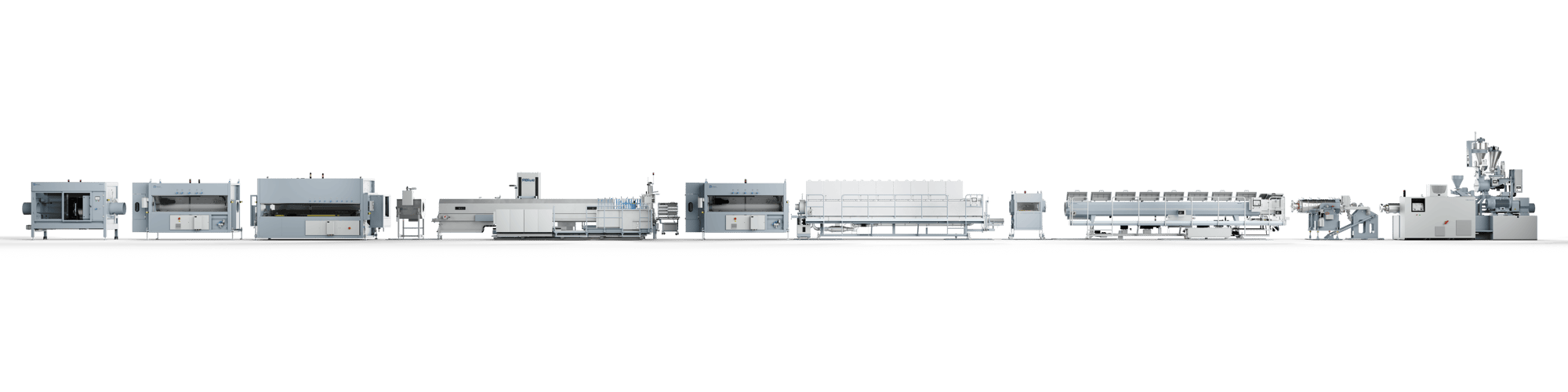

Innovative In-Line Rollepaal Technology

Rollepaal’s PVC-O technology utilizes an air-based, in-line process, allowing for a reliable and adjustable manufacturing process. This method provides several key benefits:

- Lowest production costs: Every PVC-O line is equiped with wall thickness scanning technology, which operates with gravimetric material feeding to reduce overweight automatically without operator intervention. This results in the lowest possible cost per meter of pipe.

- Consistent Quality: Integral process control results in minimal wall thickness variation, keeping overweight to an absolute minimum.

- High Production Speeds: Our system guarantees the fastest production rates.

- Automation and Efficiency: Through the hands-off principle, high automation levels reduce scrap rates and enhance production efficiency.

- Flexibility: The extrusion process easily supports the production of different pipe lengths.

Standard Line Configurations for PVC-O Technology

At Rollepaal, we understand the importance of efficiency and reliability in pipe production. That's why we've introduced our standard PVC-O production lines and streamlined them to drastically simplify the manufacturing process while ensuring outstanding pipe quality and performance. Our standard lines are built to easily comply with stringent global standards, including ISO 16422 and AWWA C909.

Customizable Performance

These standard lines are designed to meet specific market needs based on geographic location and the desired pipe specifications. For ISO configurations, the lines can produce pipes with diameters ranging from 90 mm to 630 mm, covering pressure classes from PN 12.5 to PN 25. Our ISO lines achieve impressive outputs of up to 1,000 kg/hr, even for the largest pipe sizes within this range.

Similarly, our AWWA lines cater to pipe diameters from 4" to 24", supporting pressure classes between 235 PSI and 305 PSI, with options available for applications requiring 165 PSI. This versatility makes them ideal for a broad spectrum of applications, including water distribution, irrigation, and infrastructure projects.

Groundbreaking Inline Production Process

Unlike other systems that require specialized formulations or complex setups, Rollepaal's PVC-O production lines use a standard PVC formulation, eliminating the need for special additives. This inline production process minimizes downtime, reduces material costs, and ensures consistent pipe quality while achieving the necessary molecular orientation to produce high-quality PVC-O pipes.

| Rollepaal PVC-O line | Smallest diameter | Largest diameter | Output fastest pipe | Length of pipe per hour |

|---|---|---|---|---|

Rollepaal PVC-O 250 |

90mm |

250mm |

400 kg/hr |

330 meter |

Rollepaal PVC-O 400 |

90mm |

400mm |

700 kg/hr |

380 meter |

Rollepaal PVC-O 630 |

315mm |

630mm |

1000 kg/hr |

100 meter |

Rollepaal PVC-O 12" |

4 inch |

12 inch |

1540 lbs/hr |

980 feet |

Rollepaal PVC-O 24" |

12 inch |

24 inch |

2200 lbs/hr |

200 feet |

Westlake Testimonial

Watch the testimonial of the customers of our PVC-O partner- Westlake. All together, hand in hand towards fulfilling our mission.

Sustainability Testimonial

Watch a segment from the TV show 'Earth with John Holden' and find out how Rollepaal, together with partners, is contributing to a better world.

Explore the Innovative World of PVC-O: Production Processes, Technological Evolution, and Performance

Understand the PVC-O production techniques, technological advancements, and the superior performance attributes that set PVC-O apart in the industry. From the birth of bi-oriented pipes to the evolution to inline processes, and the innovative Rollepaal PVC-O production - our guide provides an informed and in-depth look into this remarkable material.

Product Sheet

PVC-O

Explore the technical specifications of our PVC-O Technology and unleash their potential in your extrusion process.