Multi-Layer Pipe Scanners

SEE THE LAYERS. STOP THE SCRAP.

Scrap rate isn't a metric.

It's a blind spot.

Every time your multi-layer pipe fails an impact test, you lose full pallets of produced pipe. Traditional Quality Control methods don't see the layer distribution in time. Now, you can.

Use less material.

Keep the quality.

Most producers waste plastic material to stay safe. You overcompensate, because you can’t see what’s inside the pipe. Now you can.

This scanner gives you layer-by-layer visibility, so you don’t have to build in “just-in-case” tolerances. You see the actual distribution. You correct early.

Reduce unnecessary material use without compromising strength or quality.

Precision You Can See

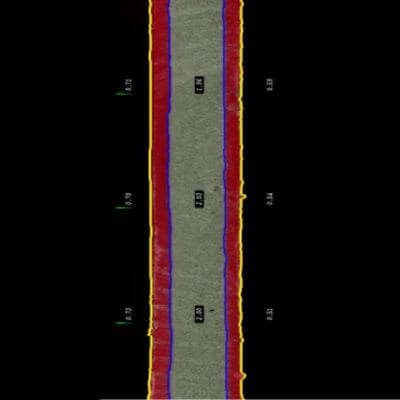

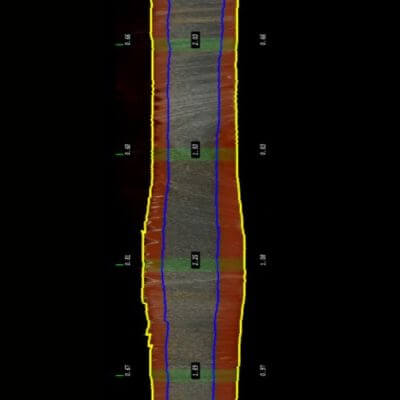

On the left side is the old pipe. On the right side, the pipe after process improvement

Break the Rules. Not the Pipe.

Layer Thickness

The first and only scanner that can measure individual layers of a pipe.

Speed Boost

Measure diameter, ovality, and foam structure in just 30 seconds, 90% faster than manual methods.

Automated Reporting

Get results in both PDF and CSV formats for instant documentation.

"We used to find out too late.

Now we fix it before it becomes a problem."

Plant Manager, pilot customer

Which Scanner Fits Your Operation?

You have two options to bring layer‑visibility into your production line.

Choose what matches your flow, or talk to us, and we’ll help you decide.

| Feature / Use Case | Offline Scanner | Inline Scanner |

|---|---|---|

|

|

|

Location |

Off line (post production or quality control station) |

In line, integrated into your extrusion line |

Purpose |

Batch sampling, spot checks, lab-based testing |

Real time monitoring and continuous feedback |

Speed |

Up to 30 seconds per pipe |

Depending on line speed |

Integration |

Portable unit with simple setup |

Integrated into your production line |

Use When... |

You need to validate sample pipes or audit batches |

You want continuous control |

Best For |

Labs, smaller lines, or occasional checks |

High throughput and tightly controlled production environments |

Real Data. Real Savings.

Calculate what you're losing by not knowing your layers:

Multi-Layer Offline Scanner ROI Calculator

What You Get With The Offline Scanner

- Industrial flatbed scanner

- Dedicated industrial PC with pre-installed software

- Dedicated training to get the best insights in your extrusion process

- Automated report generation system

- CSV export for ERP integration

See What Others Can’t.

Book Your Demo.

Be the first to detect, correct, and perfect your multi-layer pipe production.

.jpg?width=250&height=250&name=Offline%20scanner%20(1).jpg)