Twin Screw Extruders

Looking for a high-performance PVC pipe extrusion machine? Rollepaal’s advanced twin screw extruders are engineered for efficient, consistent, and high-output pipe extrusion.

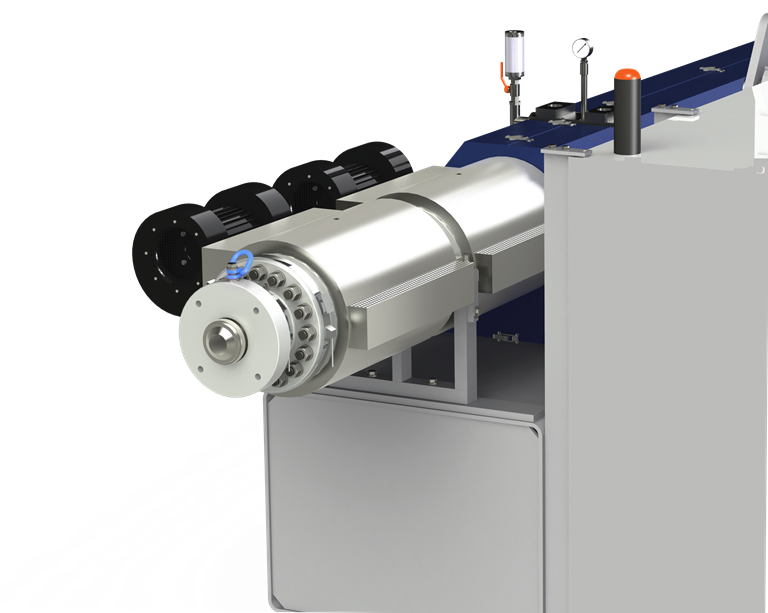

High-Performance Twin Screw Plastic Pipe Extruders

As the demand for efficient and high-quality plastic pipe extrusion grows, so does the need for advanced equipment that can deliver consistent performance and precision control. At Rollepaal, we understand the challenges faced by manufacturers in the plastic pipe industry, and that's why we have developed our Twin Screw Extruders – the ultimate solution for fast and reliable production.

Key Features of Rollepaal Plastic Extruder Machines

Our state-of-the-art Twin Screw Extruders have been designed with the latest technology to deliver exceptional performance and durability

High Production Capacity

Our extruders can produce large quantities of pipes in a short amount of time, enabling you to meet deadlines without sacrificing quality

Precision Control

You will never have to worry about the quality or consistency of your pipes with our advanced control systems that offer accurate control over the extrusion process

Durability

Rollepaal's extruders have been built to last, ensuring minimal downtime and reduced maintenance costs

Large-Scale Production Targets with Rollepaal's Twin Screw Extruders

Rollepaal's Twin Screw Extruders offer impressive output capabilities of up to 1800kg/hr or 4000lb/hr, enabling manufacturers to meet high-volume production targets with ease while maintaining quality and efficiency

Enhanced Screw Design: The Key to Efficient Extrusion

One of the most significant features of Rollepaal's Twin Screw Extruders is the improved screw design, resulting in a longer effective screw length. This design enables the production of a more homogeneous melt, wide processing window, and a reduction in production reject rates.

Consistent Output with Direct Torque Control

Rollepaal extruders utilize direct torque control, ensuring a constant screw rpm and reducing variations in output quality. This feature allows manufacturers to produce consistent pipes, with minimal wastage and reduced downtime.

High Efficiency in PVC Pipe Production with Direct AC Drive Extrusion Machine Technology

Rollepaal pvc pipe extrusion machines, including twin screw extruders and conical twin screw extruders, feature a highly efficient direct AC drive for lower energy use, reduced costs, and minimal environmental impact. Ideal for pvc pipe manufacturing, tubing extrusion, and recycled plastic extruder applications.

Operator-Friendly Windows-Based Controls with Recipe Storage

Our Twin Screw Extruders feature Windows-based controls, reducing training requirements and making them accessible to operators with varying technical know-how. The user-friendly interface ensures operators can adjust settings to achieve the desired results. The extruders also incorporate recipe storage capability to enhance reproducibility and produce consistent results.

Commitment to Quality and Efficiency

At Rollepaal, we are committed to delivering Twin Screw Extruders that optimize the production process for our customers while upholding the highest quality standards. As the above mentioned indicates, our superior machines offer numerous features and benefits that translate to increased efficiency and reduced manufacturing costs for our customers while ensuring the receive reliable and top-performing equipment.

Precise Temperature Control for Improved Quality

Our extruders feature internal screw cooling for precise control over the melt temperature, resulting in improved pipe quality and consistent output. The air-cooled barrel further optimizes the cooling process, producing pipes that meet the required specifications.

Plastic Pipe Extrusion Machine Range & Output Capacity

Explore Rollepaal's extensive range of T-Rex type Twin Screw Extruders designed to achieve maximum output capacities ranging from 150kg/hr (330lb/hr) to 1800kg/hr (4000lb/hr). Our extruders are available with effective length to diameter (L/D) ratios of 22, 30, 33 or 36, depending on your specific needs and applications. With screw diameters starting from 72mm and going up to 143mm and motor power capabilities extending from 20kW to 220kW, we offer a comprehensive selection of machines. Regardless of the scale, complexity, or requirements of your extrusion project, Rollepaal has the advanced, efficient, and precision-engineered solution for you.

|

T-Rex |

70-22 |

75-22 |

75-30 |

75-33 |

90-30 |

90-33 |

105-30 |

105-36 |

125-33 |

140-33 |

|---|---|---|---|---|---|---|---|---|---|---|

|

Maximum output |

150/ 330 |

250/ 500 |

400/ 880 |

500/ 1100 |

650/ 1430 |

800/ 1760 |

1000/ 2200 |

1150/ 2400 |

1400/ 3000 |

1800/ 4000 |

|

Effective L/D ratio |

22 |

22 |

30 |

33 |

30 |

33 |

30 |

36 |

33 |

33 |

|

Screw diameter (mm) |

72 |

75 |

75 |

75 |

91 |

91 |

107 |

107 |

127 |

143 |

|

Motor power (kW) |

20 |

25 |

45 |

55 |

75 |

75 |

110 |

140 |

160 |

220 |

Produce High-Quality Plastic Pipes at a Competitive Price

Efficient Production

High production capacity and precision control enable you to meet customer demands more quickly and efficiently

Pipe Quality

Our extruders reduce reject rates and optimize the quality and homogeneity of the melt, resulting in consistent, high-quality pipes

Cost-Effectiveness

Minimal downtime and reduced maintenance costs combined with higher efficiency and productivity means manufacturers can reduce material costs and improve their bottom line

Product Sheet

Product Sheet

Twin Screw Extruders

Explore the technical specifications of our Twin Screw Extruders and unleash their potential in your extrusion process.