Solid Wall Pipe Scanners

Easy Integratable Quality Control

Streamline Your Pipe Manufacturing Process with our Pipe Scanners

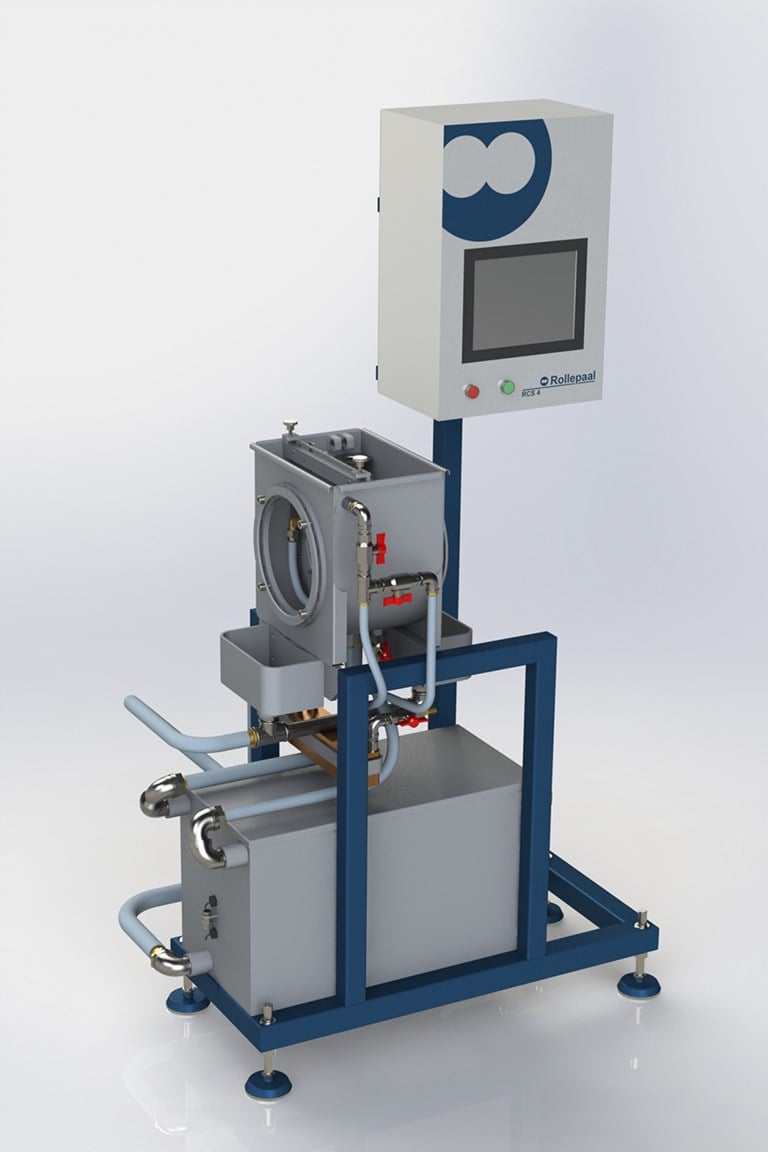

At Rollepaal, we understand the importance of quality control in pipe manufacturing. Our advanced Pipe Scanners offer cutting-edge technology and innovative features to optimize your pipe production process. With precise inspection capabilities, real-time monitoring, and easy integration, our scanners help you achieve high-quality output, reduce waste, and streamline your entire manufacturing workflow.

Key Benefits

- Enhanced Quality Control - Our Pipe Scanners provide accurate and reliable inspection results, allowing you to identify and correct any defects or inconsistencies in real-time. This ensures that only high-quality pipes are delivered to your customers.

- Increased Efficiency - By automating the inspection process, our scanners reduce the need for manual inspections.

- Reduced Waste and Rework - With the ability to detect defects early in the manufacturing process, our scanners help minimize waste and the need for rework. This reduces material costs, saves time, and ensures that your production runs smoothly.

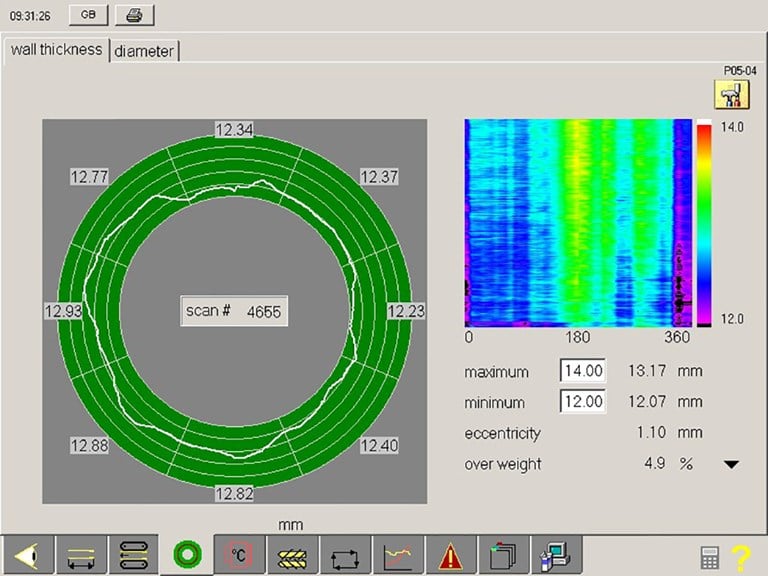

- Real-Time Monitoring and Reporting - Our scanners offer real-time monitoring and reporting features, enabling you to track production status, identify potential issues, and make informed decisions promptly.

- Easy Integration - Our Pipe Scanners seamlessly integrate with your existing pipe manufacturing systems and software, providing a hassle-free implementation process. This ensures a smooth transition and minimal disruption to your production operations.

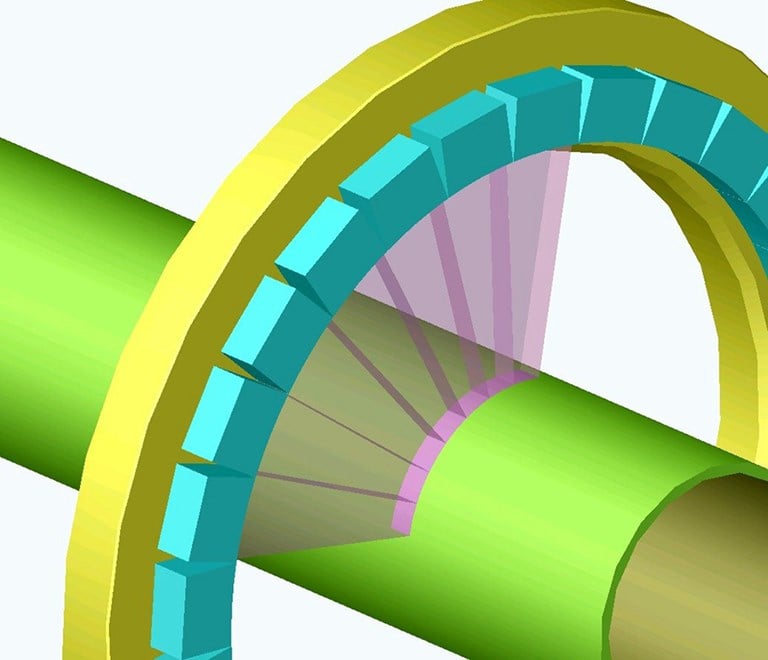

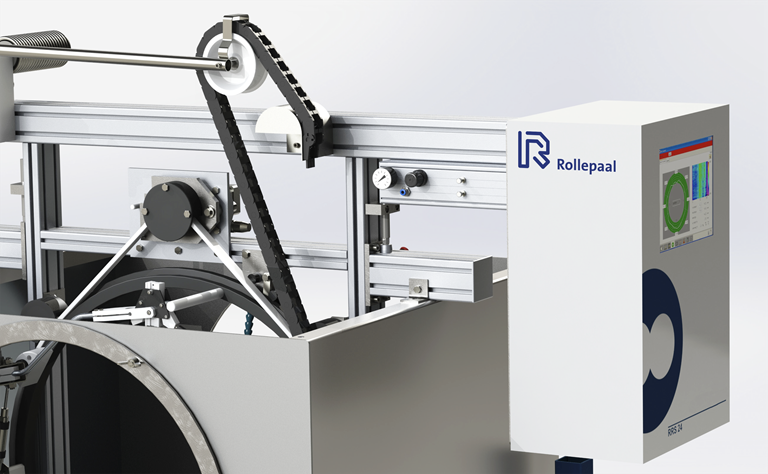

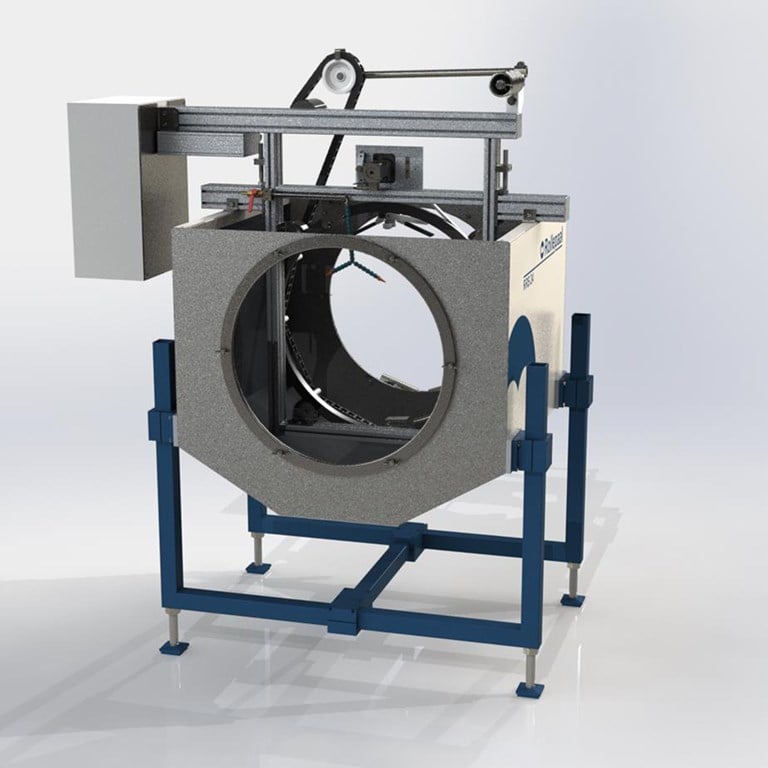

Both Rotating and Static Scanners

Our pipe scanners come in both rotating and static variants, providing flexible options to suit your specific needs. Whether you choose the rotating scanner for measuring wall thickness or the static scanner for other types of inspections, both options deliver accurate and reliable results. With advanced technology and precise measurements, these scanners ensure high-quality output and peace of mind for your production process.

Integrated Software

Our scanners feature integrated software in the central controls, allowing for seamless communication and efficient data management. With the software integrated directly into the controls, you can easily access and analyze inspection results, monitor production trends, and make data-driven decisions. This streamlined integration enhances your workflow and contributes to improved overall productivity and quality control.

Usable in Other Production Lines

Not only are our scanners designed for Rollepaal pipe extrusion lines, but they are also applicable in other production lines. This versatility allows you to maximize the utilization of the scanners across various extrusion lines, ensuring consistent and reliable quality control. By investing in our scanners, you can enhance efficiency, reduce scrap, and achieve optimal results in multiple production lines, improving your overall operational performance.

User-friendly Operator Interface

Our scanners feature a user-friendly operator interface. The intuitive controls and clear visualizations make it easy for operators to navigate the system and make adjustments according to specific requirements. This user-friendly interface increases productivity, minimizes errors, and ensures that operators can utilize the full capabilities of the scanners without extensive training.

Reduction of Startup Time and Scrap

With our advanced pipe scanners, you can significantly reduce startup time and minimize scrap. By conducting accurate inspections in real-time, the scanners identify and address potential defects or inconsistencies early in the production process. This proactive approach helps prevent costly issues downstream.

Suitable for Solid Wall PVC, PE, PP, CPVC, and PVC-O Pipes

Our pipe scanners are engineered to be compatible with a wide range of solid wall pipes, including PVC, PE, PP, CPVC, and PVC-O pipes. Regardless of the material you work with, our scanners deliver accurate and reliable measurements, ensuring quality control across different pipe types. With this versatility, you can confidently integrate our scanners into your production process, knowing that they are specifically designed to accommodate your pipes' unique characteristics and requirements.

Product Sheet

Product Sheet

Scanners

Explore the technical specifications of our Scanners and unleash their potential in your extrusion process.