2 min read

Double your PVC pipe output with Rollepaal Solid Wall Die-Heads

Michan Katerbarg Mar 27, 2025 9:56:30 AM

In PVC pipe manufacturing, the quality of your die-head directly impacts your production efficiency and pipe quality. At Rollepaal, we've reimagined the extrusion process with our cutting-edge solid wall die-heads, setting a new industry standard. Let's explore why our die-heads are the smart choice for forward-thinking manufacturers.

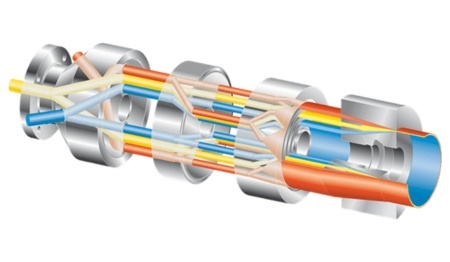

Understanding Traditional Solid Wall Die-Heads

Conventional die heads typically use a single compression design with a spider-style mandrel. The spider plate connects the core of the die head to the outside.

%20(1).png?width=500&height=350&name=Figure%203%20(1)%20(1).png)

.png?width=500&height=350&name=Figure%203%20(2).png)

Here's how they work:

- Hot PVC melt enters the die-head

- The material flows around spider legs, creating separate streams

- These streams rejoin after passing the spider, forming weld lines

- The material exits through a single opening to form the pipe

While functional, this design has limitations:

- Weld lines can be weak points in the pipe

- Weld quality depends on compression and residence time

- Limited production speeds to maintain quality

- Large die-head size is used to obtain compression, but this leads to higher residence time, which may require a higher (more expensive) formulation.

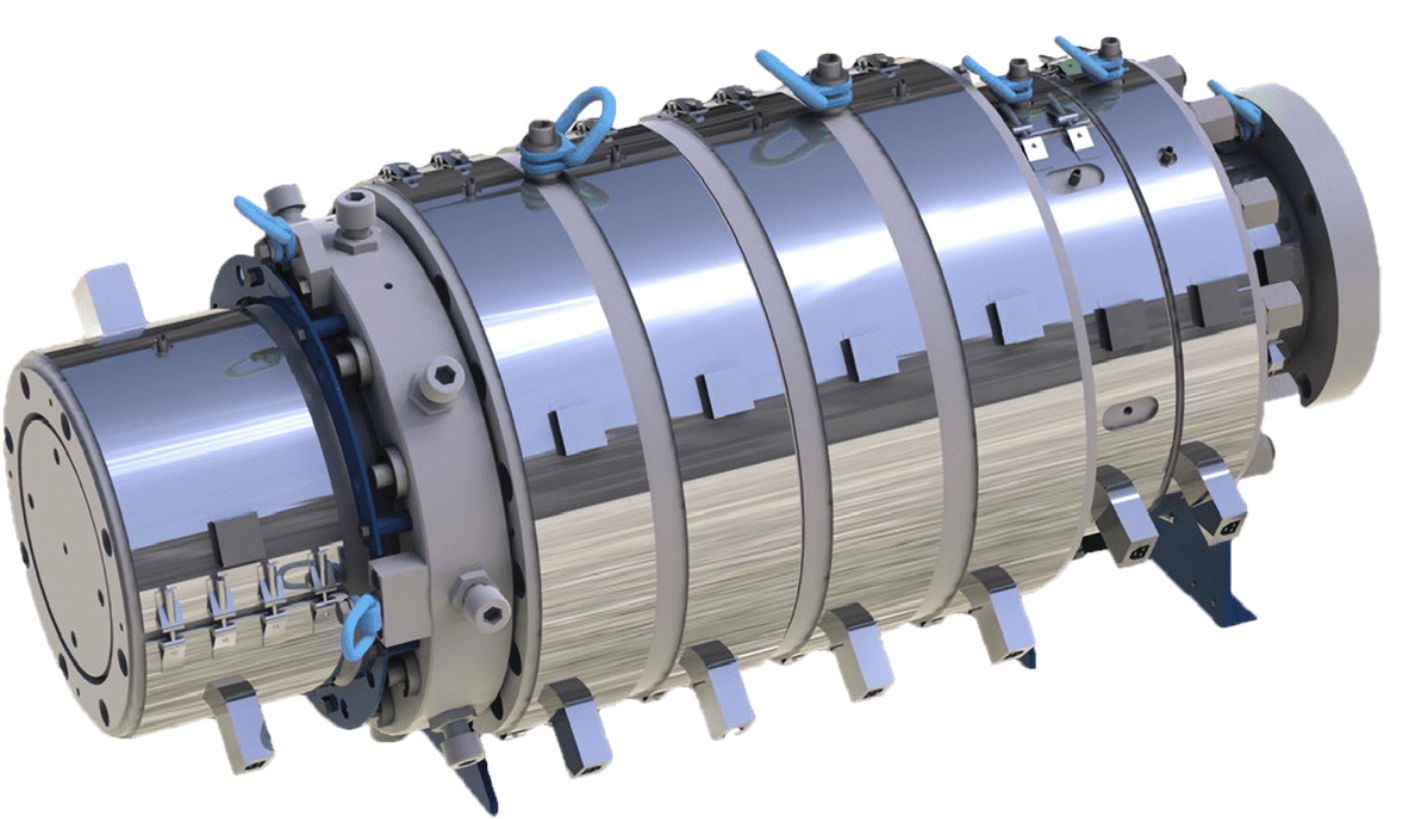

The Power of Rollepaal Double Compression

Our unique double compression design is at the heart of Rollepaal's die-head innovation. Unlike conventional single spider die-heads, our double compression technology offers:

.png?width=500&height=350&name=Figure%203%20(3).png)

- Superior Weld Line Quality: Our design ensures flawless spider line welding, producing more substantial, durable pipes.

- Unmatched Speed: Double compression allows for significantly higher production rates without compromising quality.

- Lower cost in Formulations: Our die-heads work with lower volume, resulting in lower formulation costs.

The result? You can double your output or improve quality at your existing production rates. It's a game-changer for productivity and profitability.

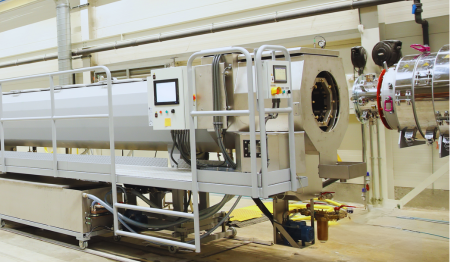

Compact Design, Massive Benefits

Rollepaal's solid wall die-heads are notably more compact than competitor models. This seemingly simple difference translates into a host of advantages:

- Easy Integration: Our smaller die-heads easily fit into existing production lines, reducing upgrade costs.

- Improved Handling: The die-head's modular construction and compact design simplify installation, removal, and maintenance.

.png?width=500&height=350&name=Figure%203%20(4).png)

- Reduced Maintenance: With fewer components, our die-heads require less upkeep, saving you time and money.

- Resource Efficiency: The smaller volume means less stabilizer usage, reducing material costs.

- Smart Centering: Changing diameter tools without affecting the die centering results in low scrap amounts during tool changes.

Precision and Control options

Our solid wall die-heads aren't just compact; we can add on features that ensure unparalleled precision and control:

- Thermal Centering: Engineered temperature control zones allow rapid wall thickness adjustments, ensuring consistent, high-quality output.

- Hoisting Tools: Allow horizontal installation, adding flexibility to your setup options.

- Quick Tool Change: This feature enables swift modifications, minimizing downtime during product changeovers.

The Bottom Line

Investing in Rollepaal's solid wall die-heads means:

- Higher quality output

- Increased production speeds

- Lower material costs

- Reduced maintenance requirements

- Greater flexibility in your manufacturing process

And here's the kicker: despite offering superior performance, our die-heads typically represent a lower investment than competitor models.

Real-World Comparison

Let's compare a standard die-head with Rollepaal's solution for producing a 315mm, 16 Bar UPVC pipe:

Aspect |

Standard Single Compression Die-Head |

Rollepaal Double Compression Die-Head |

Volume |

177 liters |

85 liters |

Flowline |

900 mm |

500 mm |

Material Residence Time |

17 minutes |

8.5 minutes |

The Rollepaal die-head processes the same output using less than half the volume. This means less material waste and lower stabilizer requirements, which results in lower material costs!

Conclusion

Rollepaal's solid wall die-heads offer clear advantages over traditional designs. By choosing our technology, you buy equipment and invest in improved efficiency, superior quality, and long-term cost savings.

Ready to upgrade your PVC pipe production? Contact Rollepaal today to learn how our innovative die-heads can benefit your operations.