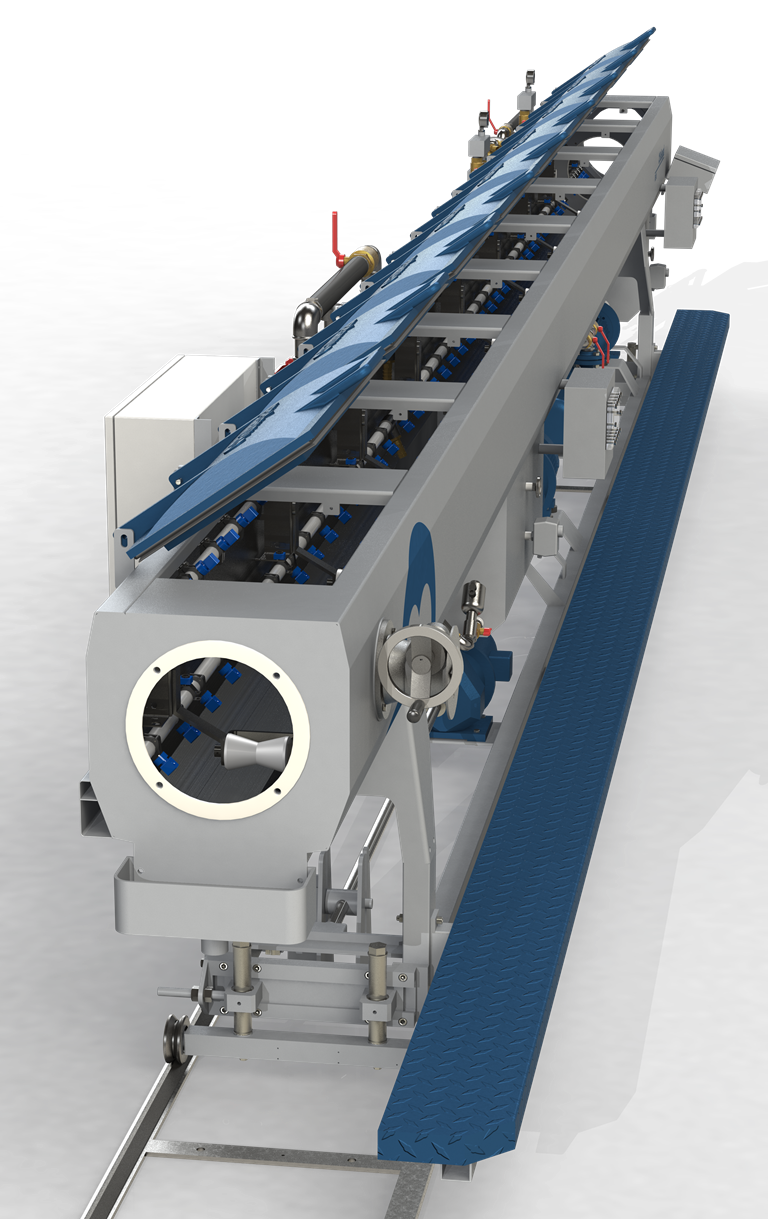

Pipe Cooling Units: Superior Cooling Solutions

Discover our advanced pipe cooling units that provide efficient and reliable cooling for pipe extrusion lines

Producing a pipe is one thing: cooling it down without it losing its perfectly round shape is definitely something else. We can do both.

Key Benefits:

- Enhanced Cooling Efficiency: Our pipe cooling units are engineered to provide superior cooling performance, ensuring rapid and effective cooling of pipes.

- Improved Product Quality: By maintaining the optimal temperature during the cooling process, our units help prevent deformations and ensure the highest quality of finished products.

- Reduced Downtime: With our reliable cooling units, you can minimize production downtime caused by inefficient cooling, leading to increased productivity and cost savings.

- Energy Saving: Our units are designed with energy-saving features to minimize energy consumption and reduce operational costs.

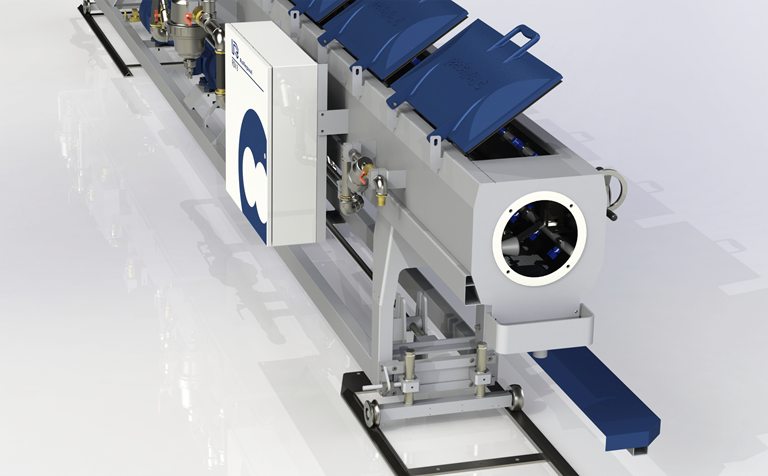

Types of Rollepaal Cooling Units

With a maximum diameter of up to Ø 2000-mm, our cooling units can accommodate a wide range of pipe sizes. We offer two versions for you to choose from, each with its own unique benefits.

Rollepaal Vacuum Cooling

Designed and manufactured with the utmost quality in mind, these vacuum cooling tanks are not only top-notch in performance, but they are also incredibly user-friendly. You'll find them easy to operate, install, and maintain, enabling a smooth and hassle-free cooling process.

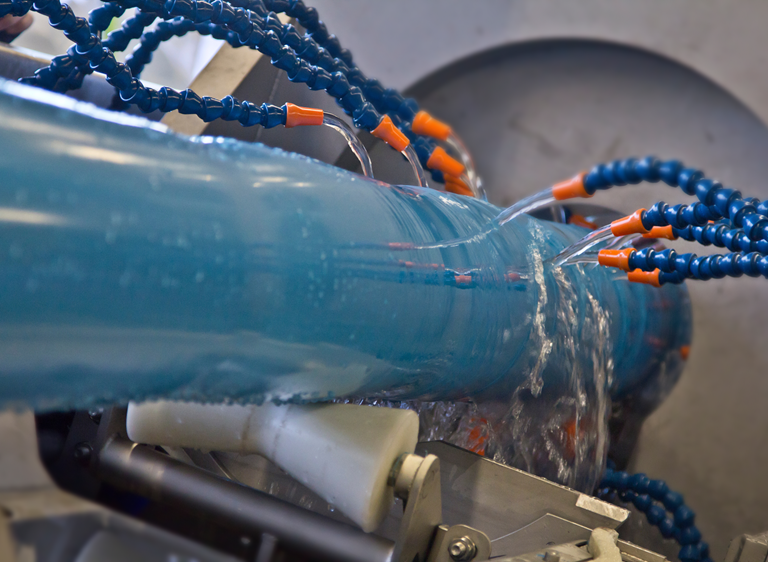

Rollepaal Spray Cooling

This innovative cooling system is stationed behind the vacuum cooling section. By spraying water on the pipe under atmospheric conditions, it provides an additional level of cooling, ensuring optimal results. With this spray cooling technology, you can further enhance the efficiency of the cooling process for your pipes.

Connection to Line Control

Our pipe cooling units are seamlessly integrated with line control systems, allowing for a smooth workflow. The connection to line control enables real-time monitoring and adjustment of cooling parameters, ensuring precise temperature control and optimal cooling performance. With this advanced feature, you have complete control over the cooling process, enhancing productivity and ensuring consistent product quality.

Automatic Vacuum Control

With our pipe cooling units, you can experience the benefits of automatic vacuum control. This innovative feature ensures optimal cooling by automatically adjusting the vacuum level based on the specific cooling requirements. By maintaining the right vacuum level, our units prevent overcooling or undercooling, resulting in improved efficiency and minimized product defects.

.jpg?width=768&height=384&name=cooling_unit_1%20(1).jpg)

Stable Water Level

Our pipe cooling units utilize proportional level and temperature control technology, providing a more stable water level throughout the cooling process. By continuously monitoring and adjusting the water level and temperature, our units maintain a consistent cooling environment and product quality while minimize production disruptions.

Durable, Stainless Steel Construction

The robust construction of our cooling units ensures long-lasting performance and exceptional resistance to corrosion, even in demanding industrial environments. With our high-quality tank shell, you can rely on the integrity and reliability of our cooling units for years of trouble-free operation.

Experience the durability and efficiency of our pipe cooling units' stainless steel, fully welded tank shell construction!

Air-Operated Water Valves

Our pipe cooling units feature air-operated water valves, which provide precise control over the water flow during the cooling process. These valves allow for quick adjustments and accurate regulation of water supply, ensuring optimal cooling efficiency. With air-operated water valves, you can achieve consistent cooling performance, resulting in superior product quality and improved production output.

.jpg?width=768&height=514&name=cooling_unit_4%20(1).jpg)

Manual Centreline Height Adjustment

Our pipe cooling units offer manual centreline height adjustment. This flexibility enables precise positioning and alignment of the cooling unit with the production line for seamless integration and uniform cooling across the entire length of the pipe.

Manual Lateral Position Adjustment

With manual lateral position adjustment capability, our pipe cooling units provide the flexibility to align the cooling section with the production line. This feature allows for precise positioning and alignment of the pipe during the cooling process, ensuring uniform cooling and optimal results.

Product Sheet

Product Sheet

Cooling Units

Explore the technical specifications of our Cooling Units and unleash their potential in your extrusion process.